- Shipping Company Estimated Delivery Time Shipping Cost

Videos

Customer Photos

Customer Videos

Customer Reviews

Questions & Answers

FAQ

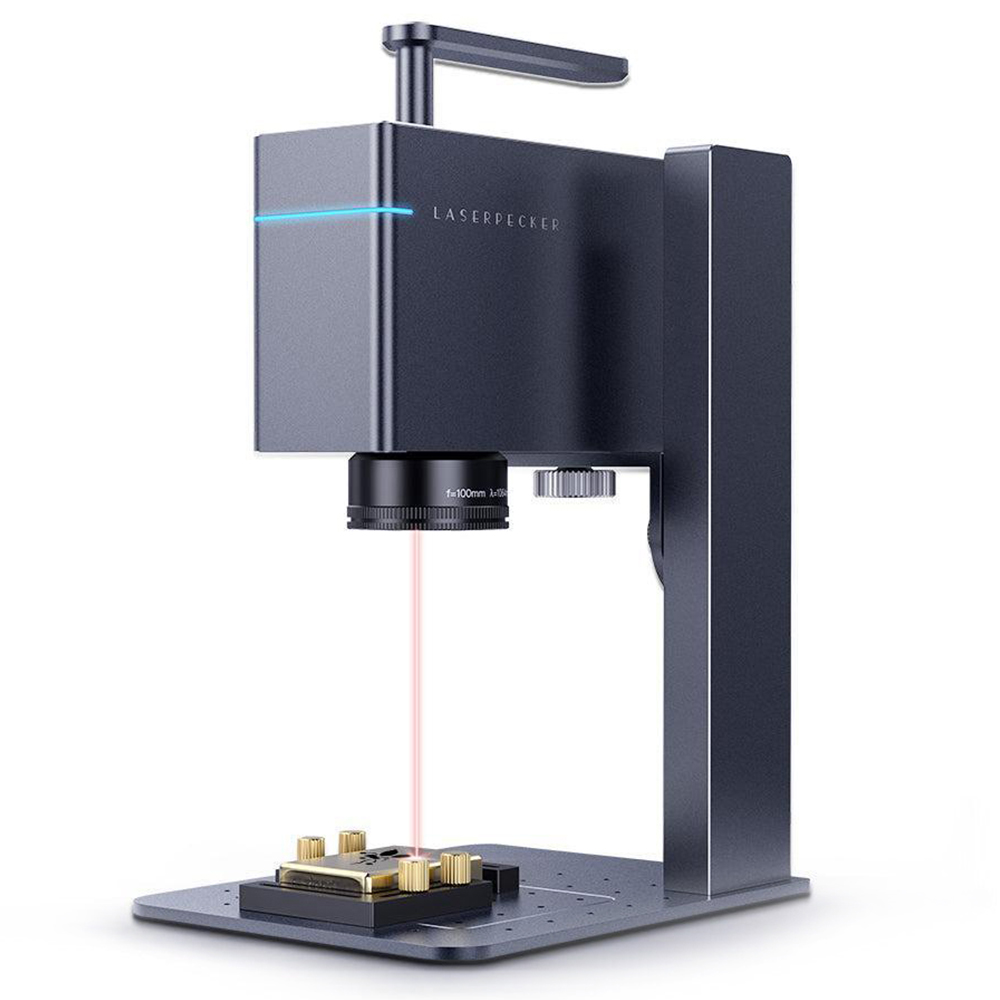

Q1: What is the power of LaserPecker 3?

A: LaserPecker 3 is a 1w, 1064nm pulse fiber engraving machine (its peak power can reach 10kw).

Q2: What is the focal of LaserPecker 3?

A: LaserPecker 3's focal length is 11.2cm to 11.5cm.

Q3: What materials can LaserPecker 3 engrave on?

A: LaserPecker 3 can engrave on almost all pure metals and alloys, like gold, silver, copper, aluminum, iron, titanium, stainless steel, and plastics like AEV, PET, acrylic, PH, and PVC without pretreatment. Besides, LaserPecker 3 can engrave on artificial leather, lacquered paper, lacquered wood, parts of stones, purple clay, etc.

Q4: What safety certifications does LaserPecker 3 have?

A: LaserPecker 3 has IEC60825-1, CE-RED, ROHS, FCC, FDA, NC, and CDRH Registered certification.

Q5: What is the difference between LaserPecker 3 and LaserPecker 2?

A: LaserPecker 2 and LaserPecker 3 are two totally different lasers-LaserPecker 2 is a diode laser, while LaserPecker 3 is a fiber laser. LaserPecker 2 can engrave on almost all common materials, but a pretreatment is needed before engraving on metal and plastics. While LaserPecker 3 is made for engraving on metals and plastics, it can achieve great results on them without pretreatment.

Q6: What is the engraving area of LaserPecker 3?

A: LaserPecker 3's ordinary engraving area is 60mm*60mm, max engraving area is 90mm*80mm.

Q7: How fast can LaserPecker 3 engrave?

A: LaserPecker 3 can engrave at the speed of 6mm/s-600mm/s.

Q8: What accessories can the LaserPecker 3 work with?

A: Accessories for LP3 are fixtures, goggles, Bluetooth dongle, and versatile electric roller.

Q9: Differences Between LaserPecker 2 and LaserPecker 3?

LaserPecker offers relatively few models, but its high price range may make many potential buyers hesitant when deciding to invest in one. After all, buying can be a big commitment, and it can be hard to change course once a choice is made.

Even when buyers consider adding a few hundred dollars to their budget, it can be challenging to determine whether the extra cost is ultimately worth it. As a result, there have been many discussions on the site about which laser engravers offer the best value in two of our most popular products, the LP2 and LP3, and whether they are worth buying.

Let me briefly introduce the main features of these two models. The LaserPecker 2 uses diode laser technology utilizing the latest compressed spot technology with a wavelength of 450nm. It's great for engraving on wood, leather, and some types of metal, but bare metal requires additional prep. To turn a diode laser into a stainless steel engraver, you need laser bond spraying. Simply spray on the adhesive marker and engrave as usual.

The LaserPecker 3, on the other hand, uses infrared laser technology with a wavelength of 1064nm and is designed for metal, plastic, and leather engraving. If metal or plastic engraving meets most of your needs, then we wholeheartedly recommend the LP3 model.

To assist in this decision-making process, we would like to highlight the main differences between the two machines in terms of parameters and applicable materials. By reviewing these distinctions, we hope customers will be able to make an informed choice that meets their needs.

| LaserPecker 2 (Basic) | LaserPecker 3 (Basic) | |

|

Applicable materials |

A broad range of materials that include painted metal, anodized metal, 304 stainless steel, bamboo, wood, leather, food, paper, cloth, photosensitive stamp, plastic, acrylic, colored glass, glazed ceramics, and more |

Metal, plastic, and leather |

|

Power |

5w |

1w |

|

Laser Type |

Diode laser |

Infrared laser |

|

Engraving size |

Common: 100*100mm |

Ellipse: 115mm*80mm Square: 65mm*65mm |

|

Focal length |

110mm |

130mm |

|

Accuracy |

0.05mm (2k resolution) |

0.005mm (4k resolution) |

|

Depth |

0.5mm |

0.05mm |

|

Laser spot |

0.05mm |

0.03mm |

|

Modes available |

Cylinder mode, Slab mode, and Trolley mode |

Only Cylinder mode |

|

Special requirement (pretreatment) |

Pretreatment required for metal and plastics |

Not required

|